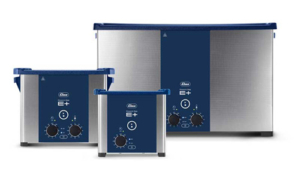

Select a Benchtop Ultrasonic Cleaner line below

Small and versatile, our benchtop ultrasonic cleaner models provide flexibility and convenience without sacrificing cleaning power. These models are best for smaller objects but come in a variety of sizes and feature options.

Small, Benchtop Ultrasonic Cleaner Applications

With the exception of the larger Select model ultrasonic cleaners featured here, most can be classified as small ultrasonic cleaners. Unlike floor mounted industrial cleaners, these relatively small ultrasonic cleaners can be easily positioned or repositioned on the benchtop to facilitate workflow. As with all equipment several points must be considered before making a purchasing decision.

Here we share purchasing criteria for a benchtop cleaner and provide some examples where they are put to work.

How Big Should My Benchtop Ultrasonic Cleaner Be?

You can’t mount a 19-inch tire on a 15-inch wheel. Similarly the dimensions (length, width, depth) of the ultrasonic cleaner’s tank must be sufficient to accommodate the largest component you plan to clean.

But there’s more: Because a majority of ultrasonic cleaning cycles take place when parts are in a basket, the basket size becomes the determining factor. Whether standard or an optional item, basket dimensions are slightly less than tank dimensions.

For example, the 2.5 gallon Elmasonic EP100H unit has internal tank dimensions of 11.80 in. x 9.40 in and 5.90 in. (LWD) but the recommended basket dimensions for this unit are 10 x 7.9 x 3 in.

You may think that a tank depth of 5.9 inches could accept a basket depth of more than 3 inches. The reason for this is that baskets are designed to position parts being cleaned at the optimum distance from the tank bottom – where ultrasonic cleaning energy is generated.

A related concern is what is called the working depth of the unit, which is the distance between the bottom of the basket and the surface of the cleaning solution. Whatever you clean should be fully immersed in the cleaning solution.

If product literature does not provide this critical information ask the manufacturer.

What Features are Important for my Small Ultrasonic Cleaner?

This is a very important consideration.

While you can purchase a unit with a simple on-off switch, for better cleaning results you’ll want one that offers a sweep mode, or a slight ± variation in frequency to provide uniform cleaning results. Units with a pulse mode provide periodic increases in ultrasonic energy to remove tenacious deposits or to process lab samples. The Elmasonic EP100H linked above offers these features.

Variable power is an attractive feature if you are cleaning a wide variety of products. This feature is offered in the Elmasonic P series.

Heavy duty cleaning requirements for ultrasonic cleaners can be satisfied by the Elmasonic xtra TT series benchtop industrial units that can operate continuously for up to 8 hours.

Applications for Small Ultrasonic Cleaners

Here are links to posts providing examples of where these ultrasonic cleaners are use and how they are used.

An ultrasonic cleaner is one of options recommended by the CDC to clean reusable dental instruments prior to sterilizing.

Read this case study on how an ultrasonic cleaner is used to clean PCBs.

Another case study on cleaning glass components used in cannabis processing.

How professionals use a small ultrasonic cleaner to clean once-fired brass cartridge casings.

Need more Info on Selecting a Benchtop Ultrasonic Cleaner?

If you need added detail please visit our post on how ultrasonic cleaners work.

We also invite you to visit our ultrasonic cleaner learning center.

Then…contact our scientists for expert advice on selecting a model best-suited for your needs, and recommendations on the best cleaning solution chemicals to get the job done right.