Ultrasonic Cleaner Accessories Broaden Business Opportunities

Investments in multifunctional ultrasonic cleaner accessories quickly pay for themselves by extending the versatility of your ultrasonic cleaner. Examples include

- For Ultrasonic Cleaning

- confidently complete challenging cleaning tasks

- use diverse cleaning chemicals in a single cleaning cycle

- In the Research Lab

- increase sample prep cycle throughput

- accommodate multiple sample prep projects in a single run

An Intro to Multifunctional Ultrasonic Cleaner Accessories

Ultrasonic Cleaner Accessories in the Shop

A cleaning basket is a cleaning basket, right? And as a professional, you know that it is not good practice to overload a cleaning basket or allow contact between parts being cleaned.

Imagine the basket of your benchtop ultrasonic cleaner as a condo or an apartment house with diverse occupants.

Consider a Modular Basket System allowing you to subdivide a simple ultrasonic cleaning basket into several compartments or levels…

…or equip it with shelves, hangers and other accouterments specifically designed to achieve maximum cleaning efficiency.

Sounds good, doesn’t it? But there is more.

Landlords and HOA boards know differences exist among occupants. Similar differences apply when selecting the correct ultrasonic cleaning solution for tasks at hand.

Here’s a solution to cleaning different small parts with different cleaning solution formulas:

Fill separate cleaning cups and inserts with the correct solution for the specific parts. These can be equipped with screen inserts to hold very small parts.

Inserts fit into special trays that positions them at the right level in the ultrasonic cleaner tank.

In these applications the tank is filled with a water bath along with a few drops of a surfactant such as a liquid dishwashing detergent. Ultrasonic cleaning energy passes through the walls of the insert to act on the contents.

For small parts cleaners, this is a boon because it allows acceptance of several specialized cleaning jobs in the same ultrasonic cleaning cycle.

Ultrasonic Cleaner Accessories in the Lab

Let’s take the condo and apartment house analogy further.

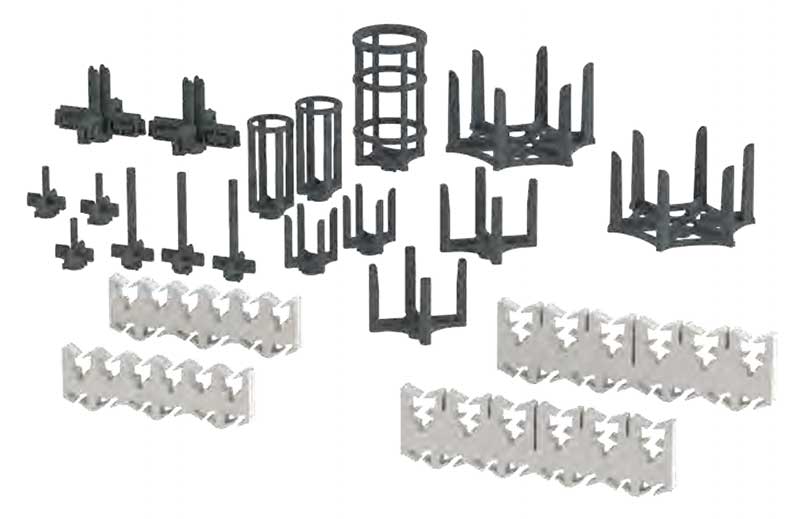

Furniture and fixtures can be likened to ultrasonic cleaner accessories such as pin sets, silicone combs, flask and test tube holders that together support a wide range of parts and containers required for sample prep tasks in the lab.

For example, you can “customize” your basket level and use your ultrasonic cleaner to accommodate various test tube, centrifuge tube and flasks of differing configurations and capacities.

As with parts cleaning described above, the tank is filled with a water bath along with a few drops of a surfactant such as a liquid dishwashing detergent. Ultrasonic energy passes through the walls of the containers to act on the samples being processed.

We offer more examples of these applications in our posts on lab applications for ultrasonic cleaners and on the role of sonicator baths in sample prep.

Other Examples of Ultrasonic Cleaning Accessories

Just as benchtop ultrasonic cleaners are available in several sizes, so too are many of the accessories available to increase the usefulness of your equipment.

- Small parts cleaning with flammable solventsrequires special precautions* but can be performed when parts are place in covered beakers partially immersed in a water-filled ultrasonic cleaner. Ultrasonic waves pass through the beaker walls and into the solvent.

- Fine screen immersion baskets are ideal for cleaning very small parts. These are placed in the regular cleaning basket or can be suspended in the cleaning solution or into beakers containing different cleaning solution formulations. Ultrasonic energy passes through the container walls to act on the contents.

- Acid-resistant tubs are required accessories when using highly acidic cleaning solutions that will damage stainless steel cleaning tanks. These are inserted in the tank partially filled with water treated with a surfactant. Ultrasonic waves pass through the tub and acts on parts immersed in the acidic cleaning formula.

- Cooling coils are called for if bath temperature increases beyond acceptable limits. Note that bath temperature increases are a byproduct of cavitation action. The coil is fitted to tank walls. Its inlet and outlet tubes are attached to a recirculating cold water supply.

- Laboratory sieve and screen cleaning is facilitated with the cleverly designed stainless steel SRH 4/200 sieve rotation holder. Electrically powered, it easily fits onto select sizes of the Elmasonic E Plus and Select series ultrasonic cleaners.

- Erlenmeyer flask clamps and test tube holders are ultrasonic cleaning accessories that position samples correctly in laboratory applications for ultrasonic baths such as performed by the Elma Select 150.

- Jewelry racksand small parts holders equipped with hooks and supported by the tank walls suspend parts in the cleaning solution.

- Electric hot air dryers quickly and gently evaporate water from sensitive parts such as jewelry.

- Noise suppressionis a critical health issue in many settings. Ultrasonic cleaners, especially those operating at lower frequencies, generate noise that can be mitigated by placing the cleaner in a noise suppression box.

Need More Info on Accessories?

Check out our page on ultrasonic cleaner accessories. It includes two videos highlighting lab and industrial applications or download the comprehensive ultrasonic cleaner accessory catalog.

In Conclusion

The scientists at Tovatech are ready to assist you in selecting and providing ultrasonic cleaning accessories that help you get the most out of your equipment investment for industry or for labs.

Please contact us for unbiased advice on the correct ultrasonic cleaning equipment and cleaning solution formulations. Our goal is to enable you to take on more cleaning and research challenges.

—————————————

*Important Note: This operation must be performed in proximity to a ventilation system ensuring that flammable vapor cannot reach an ignitable concentration near the ultrasonic tank. Check local fire regulations for the maximum quantity of flammable solvent that may be treated in an open ultrasonic tank.

———————————–